Signs Your Torque Converter Is Going Bad

Signs of a failing torque converter

A faulty torque converter can lead to a wide range of performance problems. Here are some of the more common symptoms you might notice if yours is failing.

Your check engine light is on: The car’s computer monitors and controls the operation of the torque converter. If it senses a problem, it will turn on the check engine light and log a trouble code or codes.

Your car is shuddering: A faulty torque converter can cause a shudder just before or after it locks up at cruising speed. You might feel the car shudder while driving about 30 to 45 MPH.

You notice a fluid leak: One sign your torque converter may be going bad is a transmission fluid leak. If you notice a reddish puddle under your car after it’s been sitting for a while, you’ll want to get your transmission inspected, as a low transmission fluid level can cause other serious problems.

Poor vehicle performance: A bad torque converter can cause poor acceleration. Lack of power at lower speeds is usually caused by the stator spinning incorrectly, resulting in lack of torque. On the other hand, if the stator has stopped spinning altogether, the flow of fluid from the impeller to the turbine will be inhibited. This can cause the engine to labour at highway speeds. A locked stator can also result in your transmission and engine overheating. If you notice your temperature gauge running hot, pull over to the safe spot and turn off the engine.

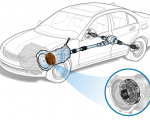

You hear a strange noise: A whirring noise under the hood can be caused by a faulty torque converter. This is usually the result of worn needle bearings inside the converter. The noise is often more apparent when the transmission is in gear. It usually eases when the transmission is shifted into neutral.

Your transmission slips: A failing torque converter can cause internal transmission components to overheat. It can also send debris throughout the transmission and result in improper fluid flow. These are serious problems and can cause the transmission to slip.

What’s in a torque converter?

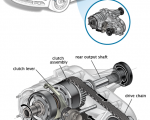

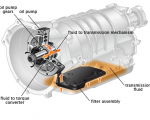

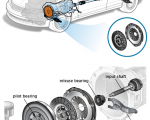

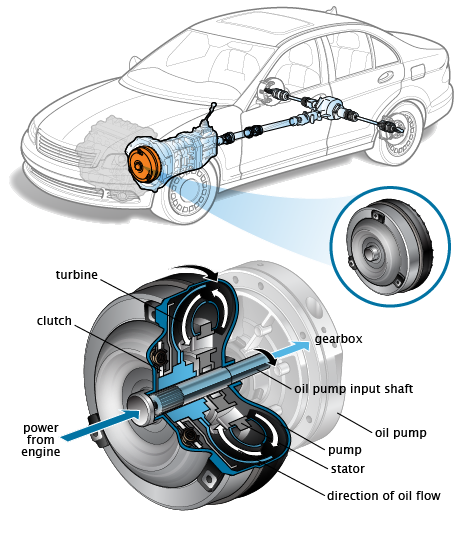

The torque converter is located between the engine and transmission. Most modern torque converters have four main parts:

- Impeller: The impeller is the torque converter input device. It attaches to the engine flywheel. When the engine runs, the impeller turns. The impeller has blades that allow it to act as a pump to get transmission fluid circulating through the converter.

- Turbine: The turbine is the converter’s output device. It is joined to the transmission input shaft. The turbine has blades that face those of the impeller.

- Stator: The stator is at the centre of the torque converter, but isn’t attached to either the impeller or turbine. It has angled blades that redirect fluid flow back to the turbine. This increases the fluid force on the turbine, and by doing so it multiplies the torque.

- Converter clutch: Some cars have a converter clutch, which mechanically links the engine and transmission, and helps prevent slippage. This is similar to what a manual transmission clutch does. The converter clutch prolongs transmission life and increases fuel economy. »

Torque converter repair advice

If you suspect a problem with the torque converter, it’s best to have a professional mechanic inspect your transmission. Diagnostic trouble codes can give you an indication of the issue, but the transmission must be removed to inspect the torque converter.

A torque converter that is discoloured from overheating is faulty and should be replaced. Stator operation can be checked by inserting a finger into the converter. The stator should only spin in one direction. If it spins both ways or doesn’t spin at all, it has failed and the converter should be replaced.

The proper fix for a bad converter is to replace it with a new unit. This can be pricey because of the amount of labour involved, and it’s important to keep in mind that torque converter problems can be caused by other internal transmission issues. Because of this, a failed converter can mean you need a new transmission. That could run you thousands of dollars.

If you’re in this situation, you’ll need to consider whether the repair is worth it. If your car is older or has a lot of miles, its value might be less than the cost of the repair. Get an estimate from your mechanic, do the math and decide if it might be better to get a new car instead.

About the Author

Mia Bevacqua is an automotive expert with ASE Master, L1, L2 and L3 Advanced Level Specialist certification. With 13-plus years of experience in the field, she applies her skills toward writing, consulting and automotive software engineering.

نوشته های مشابه